The Leading Manufacturer of Explosion Proof Elevator Equipment

We’ve helping elevator companies with elevators that are located in facilities which require explosion proof protection since the 1950’s. We offer a variety of options when it comes to meeting different explosion proof ratings and can help you with your project. The two different fixture lines we offer are noted below. For a quotation please click on the “Click Here To Get a Fixture Quote” and complete as much of the information as possible. We’ll turn your quote around within 24 hours. Some facilities requiring explosion protection are noted below.

• Grain Elevators • Oil Refineries • Coker Plants • Pharmaceutical Plants • Gas Utility Facilities • Water Treatment Plants • Flour and Feed Mills • Coal Preparation Plants • Mines • Starch, Aluminum, Sulfur, Propane, Magnesium, etc. Processing Plants

Specializing in fabricating elevator equipment for the following locations.

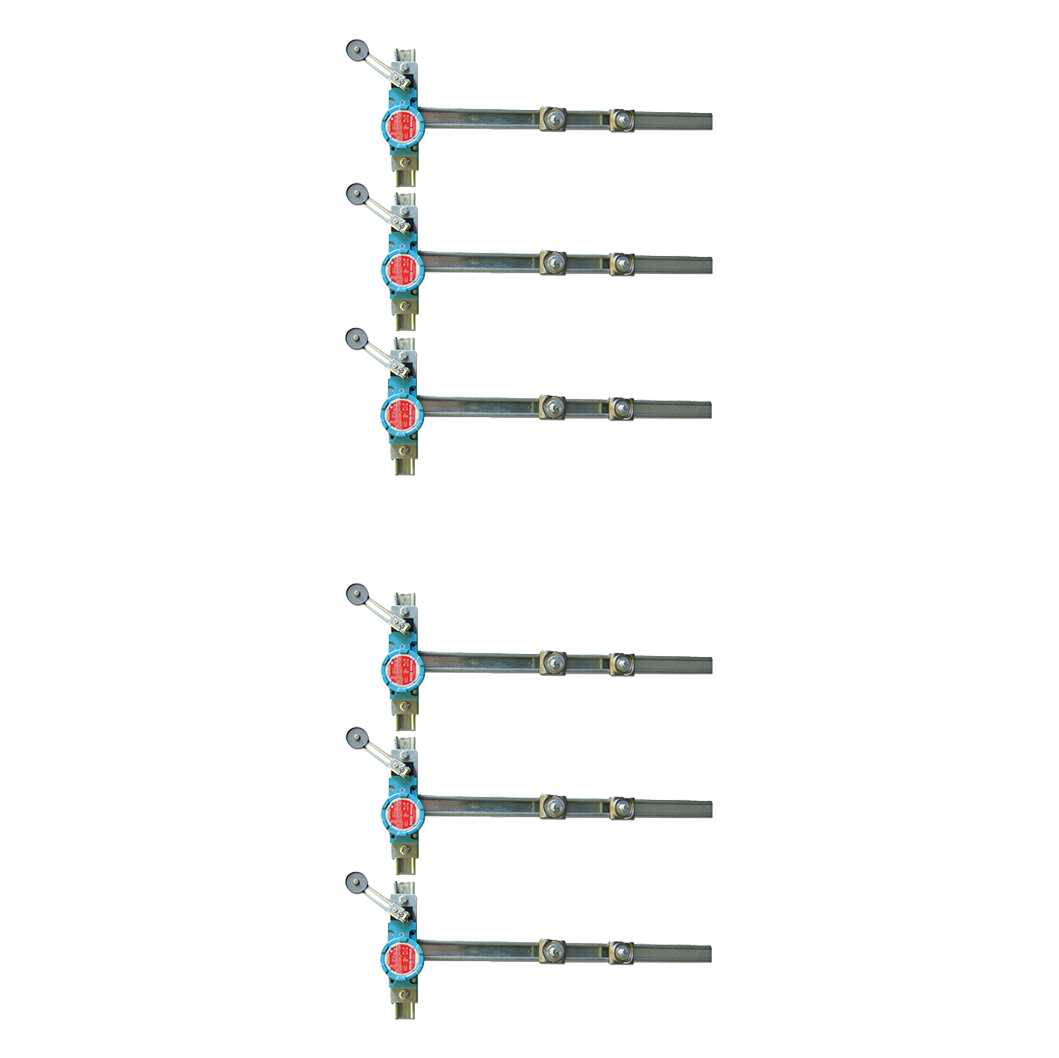

NEMA 7/9 - Class 1 & 2, Division 1 & 2 - Groups: B,C,D,E,F,G

About Hazardous Location Environmental Ratings

Hazardous location ratings indicate whether manufacturers have included safety features in products to facilitate their safe use in a hazardous environment. Those manufacturer ratings sometimes describe a product as "explosion-proof" or "intrinsically safe." It’s important to understand that not all hazardous location products are created equal. For example, a product that is safe to use around combustible dust may be dangerous if used around flammable gases. Therefore, when selecting a product, you must ensure that it's rated for use in your specific environment. Please consult with a qualified safety professional at the facility you are providing pricing for to determine the environment the elevator is in and requirements the electrical equipment needs to comply with.

The most common rating system is the Class, Division, and Group system defined by the 2017 edition of the National Electrical Code. We have briefly summarized these ratings below. For more details, see the NFPA 70 National Electric Code (https://www.nfpa.org/nec).

Classes

Classes define the type of hazardous material present in the environment.

Class I—Flammable/combustible gases, vapors, and liquids

Class II—Combustible dust

Class III—Combustible/ignitable fibers or flyings.

Divisions

Divisions define the likelihood of the hazardous material being present.

Division 1—Normally hazardous. Ignitable concentrations are present under normal operating conditions, and/or during frequent equipment maintenance or failure.

Division 2—Not normally hazardous. Ignitable concentrations occur infrequently, such as in the case of an accidental spill or failure of a ventilation system. These locations would include storage/handling facilities where the hazardous materials are kept in a sealed container or closed system. This environment can also be found adjacent to Division I areas, where hazardous materials might occasionally be communicated.

Groups

Groups define hazardous materials by rating their characteristics in relation to other known materials. Class III environments are not rated by group.

Group A—Acetylene

Group B—Hydrogen

Group C—Ethylene

Group D—Propane

Group E—Combustible metal dusts

Group F—Combustible carbonaceous dusts

Group G—Other combustible dusts.